Intact CLI 1.0.19 User’s Manual¶

Introduction¶

The Intact command line tool allows users to run a variety of physics simulations over assemblies of different geometry types. These simulations are configured with a json file. We generally refer to one of these simulations as a scenario. Code examples that are meant to be run in a shell are prefixed with $. For example

$ intact --help

will produce output that looks like:

$ intact --help

A command line interface for Intact

For more information, the user manual can be found at:

https://intact-solutions.com/intact_docs/

Usage:

Intact [OPTION...]

-h, --help Print program usage

--build-info Print report about current build, then exit

--version Print the software version

-s, --scenario arg Scenario json file

-f, --fields arg Fields to sample (if empty, all available

fields will be sampled). Comma delimited.

-o, --output arg Output directory. The default it the

directory of the scenario file.

--skip-sample Skip the sampling step of the solver.

--json-output Output the sampled results in JSON format

(VTK is the default output).

--tempdir Make a temporary directory for output

--scenario-name arg Prefix for output files, defaults to

scenario file name

--load-solution-file Load a cached solution file/s

--logdir arg Path to the log file. Default value is

current working directory.

--logname arg If not specified, log will not be put in a

file

--save-solution Save the scenario solution in vtk format

--refinement-level arg Refinement ratio w.r.t. assembly bounding

box. If not present, no refinement is

performed.

-v, --verbosity arg Verbosity level, run with --help for more

information

--define-version Software version

Aside from the syntax for paths, this documentation applies to builds of the intact tool on all operating systems. All officially supported features are documented here, though the build provided may have additional functionality.

In addition, this manual should be bundled with example simulation files. We advise looking at those as a companion to the material described here.

Example Simulation to Get Started¶

Instructions¶

Sign up for the trial to get access to our software.

The intact CLI executable is installed in C:\Users[your username]\AppData\Local\Programs\Intact.Simulation for Automation\intact.exe

Some demo examples (Mesh and VDB geometry).

Typical workflow¶

Set up the input Json and provide the geometry file (.VDB, .PLY, .STL) and boundary condition faces (.STL, .PLY)

Execute intact CLI $ intact -s “path to json file” –-save-solution –refinement-level 0.02

A successful run will result into a *_samples.vtu result file

You can visualize the result in Paraview (an opensource program, see instruction below)

Resample the saved solution on a new geometry (sections or cuts)

Modify geometry file in the original JSON to the new geometry that you want to resample on

Execute $ intact -s “path to json file” –load-solution-file –refinement-level 0.02

Viewing Results¶

The intact command line outputs VTK files. These are fairly standard, and can be manipulated in a variety of programming languages. For more information about official VTK resources please check out their homepage.

VTK - The Visualization Toolkit

There are a number of third-party libraries for working with VTK files in other languages.

We recommend using the Paraview application for viewing and manipulating these results in most cases. Paraview is an industry-standard scientific data analysis and visualization tool that is free and open-source. More information, and builds for most operating systems, are available from the Paraview home page.

Paraview Quick-start¶

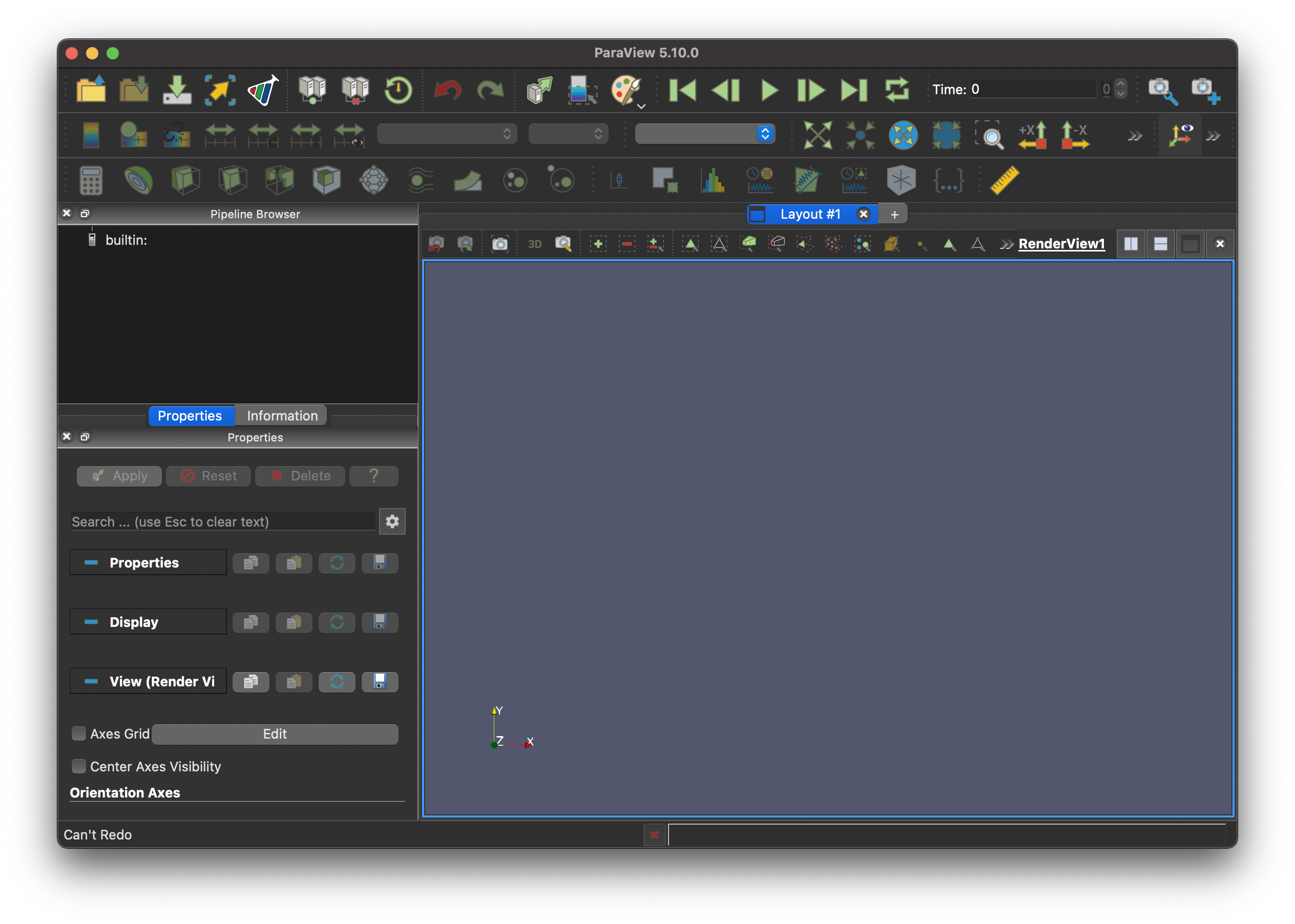

Opening Paraview should yield an interface that looks roughly like this.

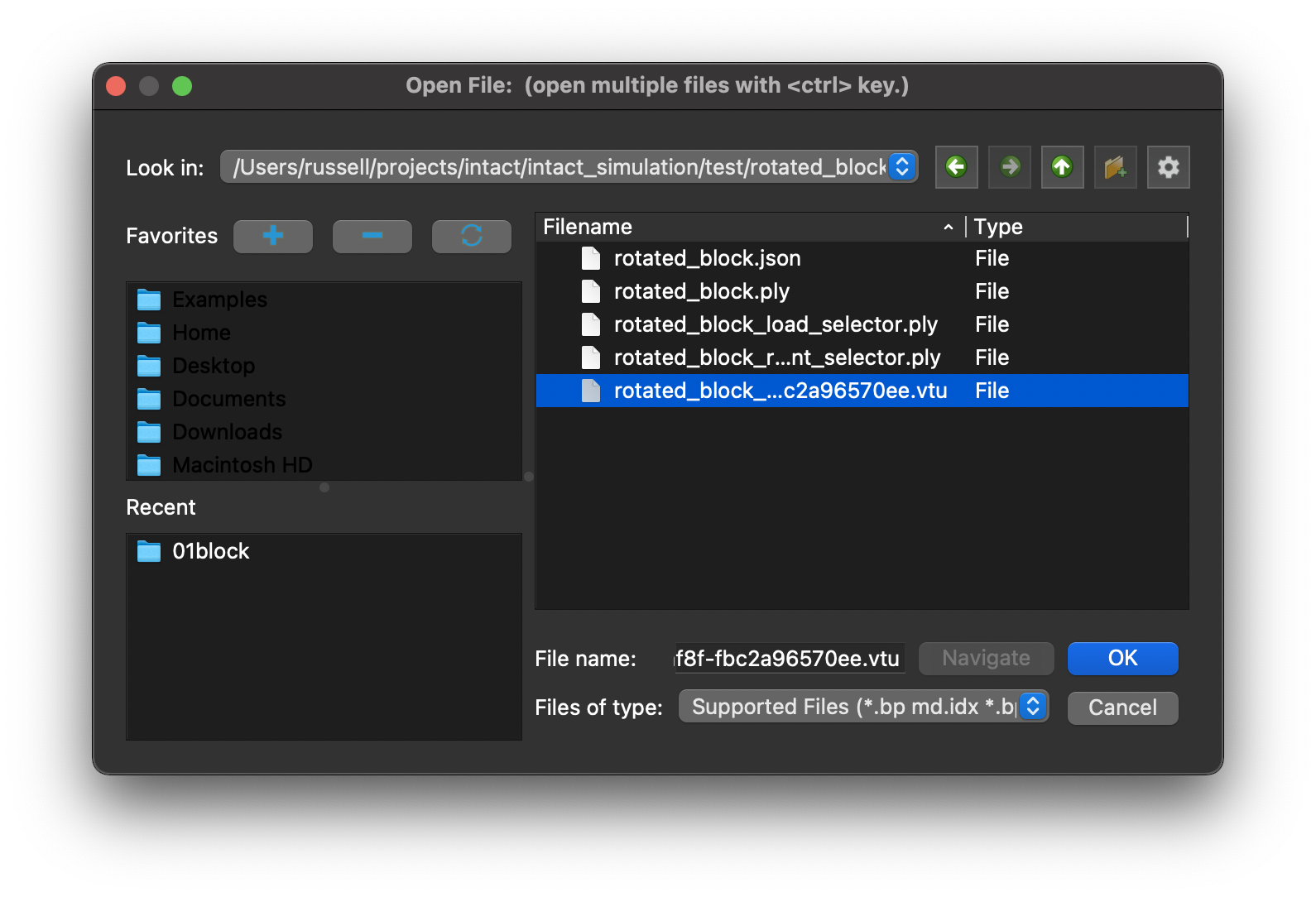

The intact command line tool will place the samples in the results directory (by default, the same directory as the json file). Look for a samples *.vtu file and open it in Paraview.

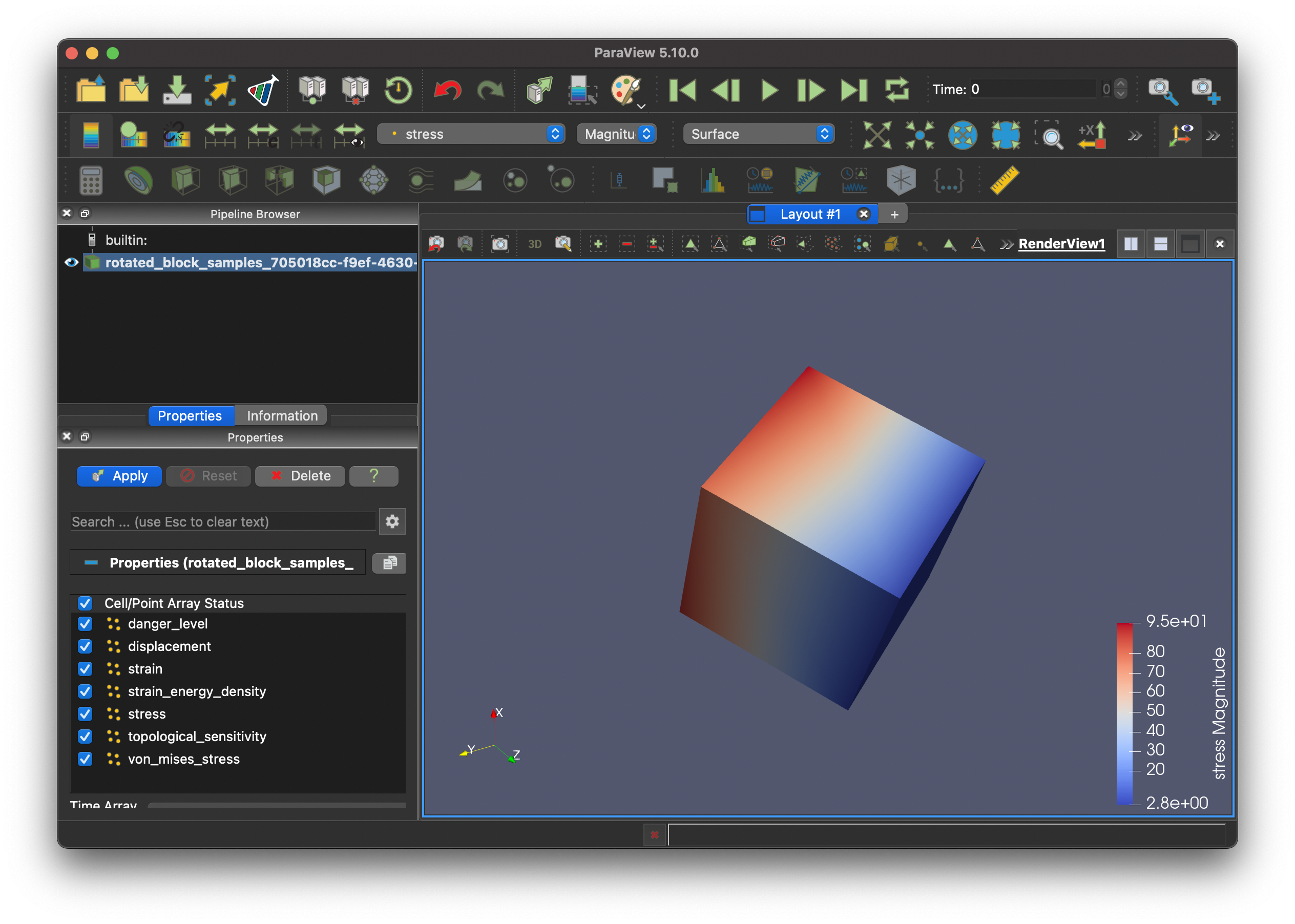

Make sure the samples are visible in the pipeline browser by clicking the eye icon.

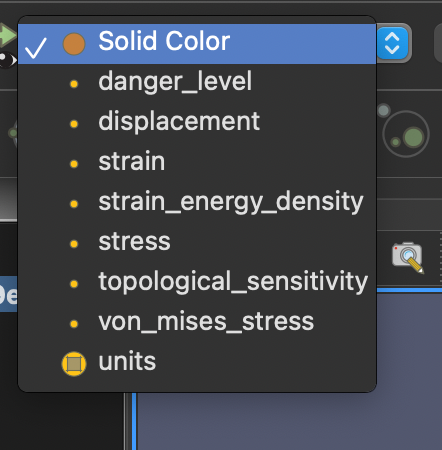

The sampled fields are available in the properties dropdown. For example the following would be typical of a linear elasticity scenario.

Here is how stress results would look. One can rotate and pan the viewport.

Command Line Options¶

Command line documentation can be retrieved with the help flag.

$ intact --help

The help documentation bundled with the tool is definitive, the most important options are covered here in more detail.

-s, --scenario <path/to/scenario.json>¶

When not calling either --help or --build-info, this option is mandatory for all calls. The tool needs a path for the scenario json file to use.

-o, --output <path/to/output_dir>¶

The tool generates a variety of output files. By default, these files will be put in the same directory as the scenario json file. Use this flag to change the directory where output files will be placed. The scenario json file, and any geometry files referenced, will be copied over to the output directory.

--refinement-level <ratio>¶

Surface and Volume mesh geometry can be refined prior to sampling. This can be a good idea if the triangle quality is poor: large triangles may not properly resolve and interpolate detail in the solution. Refining the mesh means that the ratio of element edge length to bounding box size will not exceed the refinement level provided by this option.

--build-info¶

This flag can be used to get detailed information about the version of the tool. Attaching this information to any bug reports will help with debugging.

Specifying Boundary Conditions¶

Specifying boundary conditions for Intact.Simulation is a bit different than other FEA systems. Because Intact’s technology is based on the use of a non-conforming mesh, boundary conditions are not specified directly on a finite element mesh. This also means that Intact does not support non-real boundary conditions like point and edge constraints / forces / moments.

Instead, boundary conditions in Intact are specified as triangle mesh based surfaces. These can be either *.ply or *.stl files. Specific semantics of what each boundary conditions does are specified in the section for each physics, however all boundary conditions will need to specify a surface.

Some things to keep in mind with these surfaces.

Having multiple disconnected components in one mesh will not cause a runtime error but may not yield high quality results. It is best to create a separate boundary condition instance in the json configuration for each fully connected component.

It is possible to specify a boundary condition that is disconnected from the geometry. This can result in a runtime warning, but is not an error. Note in cases where a force / quantity is distributed over the boundary condition surface this will result in some of the quantity not being accounted for since there is nothing to apply it to.

Common JSON Keys¶

The scenario json format shares a lot of structure between the different physics. The common components are detailed here. All scenario json files start with a top-level object, which contains a few common attributes.

{

"boundary_conditions": [ ... ],

"geometry": { ... },

"materials": { ... },

"metadata": { ... },

"scenario_name": "Name_for_output_files",

"type": "<physics type>"

}

Geometry¶

Specifying geometry in scenario json has two pieces. First, a collection of components must be defined. Each component has a geometry type, a file to load, a material id, and a component id. The other component to specifying geometry is an assembly of components. The material id needs to match a material defined in the materials object from the scenario object. Each component needs a unique integer id.

Geometry::Mesh¶

There are four types of geometry that can be used with components. The most common is to use a triangle mesh to specify the surface of a volume. These triangle meshes can be loaded from both ply and stl files.

{

"file": "block.ply",

"geometry_type": "Mesh",

"id": 1,

"material": "Acrylic"

}

Geometry::VDB¶

Geometry can be specified with an openvdb double grid file.

{

"file": "demo.vdb",

"geometry_type": "VDB",

"id": 2,

"material": "Steel"

}

Units¶

There are several places in the json format where units can be specified. The possible values are listed here.

"MeterKilogramSecond"

"CentimeterGramSecond"

"MillimeterMegagramSecond"

"FootPoundSecond"

"InchPoundSecond"

Boundary Conditions¶

All scenarios require the specification of boundary conditions. Different scenarios support different types of boundary conditions, but all boundary conditions have a couple of common members.

boundary¶

All boundary conditions must be applied to a specified surface. The value should be a path to an *.ply or *.stl file. This path can be relative to the location of the scenario json file. For example, if the configuration json file is in the same directory as restraint.ply then the following would be valid.

"boundary": "restraint.ply"

units¶

All boundary conditions can optionally specify units.

type¶

The type member differentiates the variety of possible boundary conditions. Each specific boundary condition will contain an example json instance that will have the value for type.

Metadata¶

There are a variety of options available that can be configured with metadata.

Either resolution or cell_size must be specified, but no other options need to specified.

Default values will be used when not specified.

units¶

The default units for the scenario, including geometry. Note that this default does not apply to materials, which will default to MKS unless specified there.

basis_order¶

The type of finite element used. The default is 1, which would be linear elements. 2 is for quadratic elements.

max_iterations_multiplier¶

This parameters changes the max iterations for iterative solvers, it scales with the number of degrees of freedom. Use a parameter less then one for faster solve times, with the tradeoff of accuracy.

tolerance¶

The tolerance for iterative solvers. The default value is 1e-20. That value is meant to achieve high accuracy at the cost of solve runtime. Increasing the tolerance will decrease solve time, but will yield less accurate results.

resolution¶

The target number of elements. An iterative process is used to determine a cell size that achieves approximately the specified number of elements. The logging output will include the resolved number of elements and cell size. Either resolution or cell_size must be specified.

cell_size¶

The cell size to use. The log output will include the resolved number of elements. When possible, specifying cell_size will skip the expensive iterative process when using the resolution parameters.

omega_cutoff¶

A parameter to tune the use of solution structure method for enforcing boundary conditions. By default, there is no cutoff, and it is not recommended to tune this parameter without additional input from Intact Solutions.

solver_override¶

The solver_override parameter can be used to explicitly specify the solver to use.

The default solver for linear elasticity and modal scenarios is AMGCL_amg_rigid_body.

The default solver for thermal scenarios is AMGCL_amg.

The following solvers are available:

// Iterative conjugate gradient solver without preconditioner.

AMGCL_cg

// Iterative conjugate gradient solver with ilu0 preconditioner.

AMGCL_ilu0_cg

// Iterative conjugate gradient solver with damped jacobi predonditioner.

AMGCL_damped_jacobi_cg

// Iterative AMG based solver with smoothed aggregation.

// This is the default solver for thermal scenarios.

AMGCL_amg

// Iterative AMG based solver with rigid body modes based coarsening.

// This is the default solver for linear elasticity.

// This solver cannot be used with thermal scenarios.

AMGCL_amg_rigid_body

// Direct solver that uses LU decomposition.

Eigen_SparseLU

// A sparse direct Cholesky (LDLT) factorization and solver based on the PARDISO library provided by Intel's MKL.

MKL_PardisoLDLT

// A sparse direct Cholesky (LLT) factorization and solver based on the PARDISO library provided by Intel's MKL.

MKL_PardisoLLT

// A sparse direct LU factorization and solver based on the PARDISO library provided by Intel's MKL.

MKL_PardisoLU

integrator_override¶

For some physics types, there may be multiple integrator implementations available;

the integrator_override configuration allows choosing among the available implementations.

In general, the default choice is the best choice.

The following integrators are available:

// Default for modal scenarios.

IntactModal

IntactLinearElasticity

// Default for thermal scenarios.

MPCStaticThermal

// Default for linear elasticity scenarios.

MPCLinearElasticity

LinearBuckling

use_caching¶

By default, Intact.simulation will cache all quadrature rules and material properties for each cell. This can use significant amounts of memory for problems with lots of elements. To really push the problem size that can be run on a given machine, caching can be turned off to decrease the memory footprint of a simulation run at the cost of additional runtime.

"use_caching": false

verbose_solver¶

Some of the sparse linear solvers used by intact can provide feedback about their progress. By default this is false, but if set to true some solvers will report their progress to standard out. For AMGCL solvers, every five iterations the iteration number and various error measurements will be printed. This can be useful for long running simulations to observe progress.

Linear Elasticity¶

Linear elasticity requires the scenario json object to have "type": "LinearElasticity".

Materials¶

Linear Elasticity and Modal scenarios both use our structural material types. All materials need a density value, and can optionally include a "units": member. Note that all materials will be specified in MKS unless units are specified.

Isotropic¶

For isotropic materials, the user must specify a failure criterion type. This is used during sampling to calculate the topological sensitivity and danger level, fields which aren’t sampled for other structural material types. The choices for failure criterion type are:

"Unspecified" // Do not calculate the danger level

"VonMises"

"MaximumShearStress"

"Rankine"

"CoulombMohr"

"ModifiedMohr"

An example of how this would look in json:

{

"compressive_strength": 690000000.0,

"density": 7200.0,

"failure_criterion": "CoulombMohr",

"poisson_ratio": 0.27,

"tensile_strength": 170000000.0,

"yield_strength": 0.0,

"youngs_modulus": 100000000000.0

}

Orthotropic¶

Orthotropic materials have material properties that vary depending on the orientation.

The elastic modulus in the x, y and z directions are defined by Ex, Ey and Ez,

the Poisson’s ratio by vxy, vxz and vyz,

and the shear modulus by Gxy, Gxz and Gyz.

The material properties can be transformed by specifying a transform matrix, for example,

to simulate composite fibers that are rotated by 45° relative to the x-axis.

The type must be Orthotropic.

An example configuration for a composite material of Kevlar and epoxy, with the fibers rotated by 45° relative to the x-axis, is shown below.

{

"Ex": 85000000000.0,

"Ey": 5600000000.0,

"Ez": 5600000000.0,

"Gxy": 2100000000.0,

"Gxz": 2100000000.0,

"Gyz": 2280000000.0,

"density": 1350,

"transform":

[0, 0.7071, 0.7071,

0, -0.7071, 0.7071,

1, 0, 0],

"vxy": 0.34,

"vxz": 0.23,

"vyz": 0.34,

"type": "Orthotropic"

}

Boundary Conditions¶

Fixed¶

Fixes the boundary at 0.

Fixed boundary conditions can be applied to both thermal and displacement fields.

Fixed displacement boundary conditions are often called restraints in other FEA systems.

{

"boundary": "restraint_selector.ply",

"type": "fixed"

}

For thermal scenarios, temperature fields can be fixed to non-zero values with the optional value field.

{

"boundary": "restraint_selector.ply",

"type": "fixed",

"units": "FootPoundSecond",

"value": 500.0

}

Fixed Vector¶

This boundary condition serves two purposes.

Fixing displacement at some non-zero value.

Partial restraints, also known as axis-aligned sliding restraints.

Displacement is a three dimensional field, and each displacement component can optionally be specified. Any axis not specified will not be restrained. The following example fixes the x component of displacement at 1, while the y and z axis are unrestrained.

{

"boundary": "restraint_selector.ply",

"type": "fixed_vector",

"units": "MillimeterMegagramSecond",

"x_value": 1.0

}

In the following example, the x axis is fixed at 1.0, while the y and z axis are fixed at 0.

{

"boundary": "restraint_selector.ply",

"type": "fixed_vector",

"units": "MillimeterMegagramSecond",

"x_value": 1.0,

"y_value": 0.0,

"z_value": 0.0

}

Sliding¶

Sliding boundary conditions prevent displacement in the direction normal to the specified surface, and permit displacement tangential to the surface. A sliding boundary condition can be used to represent a pin joint, for example.

To use a sliding boundary condition, specify the boundary where this boundary condition applies,

and specify the type as sliding, as in the following example:

{

"boundary": "restraint_selector.ply",

"type": "sliding"

}

Vector Force¶

The vector force boundary conditions will apply a force of a given direction and magnitude evenly over the prescribed surface. Vector force must specify the direction and magnitude.

{

"boundary": "surface.ply",

"direction": [

0.0,

0.0,

-1.0

],

"magnitude": 100.0,

"type": "vector_force",

"units": "MillimeterMegagramSecond"

}

Pressure Force¶

A pressure force boundary condition applies a pressure of a given magnitude opposing the normal of the boundary.

{

"boundary": "top_face.ply",

"magnitude": 100.0,

"type": "pressure_force",

"units": "InchPoundSecond"

}

Torque Force¶

Applies a torque force to the boundary. Must specify the axis and origin of the rotation, as well as the magnitude of the torque.

{

"axis": [

0.0,

0.0,

1.0

],

"boundary": "twist_load_selector.ply",

"magnitude": 100.0,

"origin": [

0.0,

0.0,

20.0

],

"type": "torque_force"

}

Hydrostatic Load¶

A hydrostatic load boundary condition simulates a body submerged in liquid,

and requires defining the boundary that may be in the liquid, the density of the liquid,

and the height the liquid rises above the z = 0 plane.

{

"boundary": "surface.ply",

"density": 300.0,

"height": 30.0,

"type": "hydrostatic_force",

"units": "MeterKilogramSecond"

}

Bearing Load¶

A bearing load occurs at the contact between two curved surfaces. The contact pressure is not uniform. It is scaled by the angle of the contact relative to the angle of the force. The specified magnitude is the total force applied over the entire surface.

{

"boundary": "bearing.ply",

"direction": [

0.0,

-1.0,

0.0

],

"magnitude": 12.0,

"type": "bearing_force"

}

Internal Conditions¶

Body Load¶

The body load simulates linear acceleration. This can also be used for gravity. It must specify the direction and magnitude.

{

"direction": [

0.0,

0.0,

-1.0

],

"magnitude": 9.80665,

"type": "body_load"

}

Rotational Load¶

The rotational load can be used for both the outward force of velocity and inertial stress from acceleration. The axis and origin of rotation must be specified, as well as the rotational velocity and acceleration.

{

"angular_acceleration": 100.0,

"angular_velocity": 0.0,

"axis": [

0.0,

0.0,

1.0

],

"origin": [

0.0,

0.0,

0.0

],

"type": "rotational_load"

}

Modal¶

Modal simulations requires the scenario json object to have "type": "Modal".

Materials¶

Supports all the same materials as linear elasticity.

Modal Metadata¶

Modal scenarios have an additional metadata field to specify the number of frequency responses to search for. For each frequency response, a corresponding displacement field will be calculated.

desired_eigenvalues¶

The number of frequency responses to search for. This is an integer value.

Boundary Conditions¶

Modal scenarios support the fixed boundary condition from linear elasticity.

Linear Buckling¶

Linear buckling simulations require the scenario json object to have "type": "LinearBuckling".

A linear buckling simulation first performs a linear elasticity simulation, then solves the

generalized eigenvalue problem

where \(K\) is the stiffness matrix, \(x\) is the displacement vector corresponding to the eigenvalue \(\lambda\) and \(K_G\) is the stress stiffness matrix calculated from the linear elastic simulation.

Materials¶

Supports all the same materials as linear elasticity.

Metadata¶

Linear buckling scenarios use the same metadata as linear elasticity scenarios and have an additional metadata field to specify the number of eigenvalues to calculate. Each eigenvalue corresponds to a critical load factor, which when multiplied by the applied load, determine the critical load. For each critical load factor, a corresponding displacement field will be calculated, which is representative of the buckling mode shape.

Because a linear buckling simulation always first performs a linear elasticity simulation,

the solver_override metadata provides control of the solver type for the linear

elasticity simulation. The linear buckling solver is selected automatically.

desired_eigenvalues¶

The integer number of critical load factors to solve for.

Boundary Conditions¶

Linear buckling scenarios support the same boundary conditions as linear elasticity.

LevelOpt¶

LevelOpt is a level set structural topology optimization simulation (compliance minimization) which requires the topopt.exe to run and supports different CLI arguments. The scenario JSON file has a similar format to standard LinearElastic scenario JSON files with additional scenario "shape_exploration_data": {} information. A LevelOpt optimization performs a linear elasticity simulation and uses "Type": "LinearElasticity".

$ topopt --help

will produce output that looks like:

$ topopt --help

A command line interface for Intact.Simulation topoology optimizer.

Usage:

topopt [OPTION...]

-h, --help Print program usage

--version Print the software version

--sample-sensitivity Sample the sensitivity on the provided sampling

points

-s, --scenario arg Scenario json file

Materials¶

Supports all the same materials as linear elasticity.

Metadata¶

Supports all the same metadata as linear elasticity.

Because LevelOpt always first performs a linear elasticity simulation,

the solver_override and integrator_override metadata provides control of the solver for the linear

elasticity simulation.

Boundary Conditions¶

LevelOpt scenarios support the same boundary conditions as linear elasticity. Note additional load_case_id can be used for setting up multiple load cases

"boundary_conditions": [

{

"boundary": "fixed1.stl",

"type": "fixed",

"load_case_id": 0

}

]

Shape Exploration Data¶

"shape_exploration_data": {

"enable_fixed_interfaces": true,

"opt_max_iter": 50,

"vol_frac_cons": 0.2,

"level_set_cell_size": 1.0,

"move_limit": 1.0,

"component_id": 0,

"smooth_iter": 1,

"fix_thickness": 4.0,

"num_load_cases": 13,

"starting_design_file": "" //"starting_design_file": "starting_design.ply"

}

vol_frac_cons¶

Sets the target volume of the final design as a fraction of the initial volume. (volume fraction constraint)

level_set_cell_size¶

Determines the size of the level set grid cells as a fraction of the FEA grid cell size. (level set cell size)

move_limit¶

Controls the extent of changes per optimization step, as a factor of the voxelSize.

component_id¶

Specifies which component id in the "components": [] list is to be used as the design domain for assembly optimization.

opt_max_iter¶

Sets the maximum number of iterations for the optimization process. Each iteration refines the design by updating the topology based on the objective function and constraints. (optimization max iterations)

fix_thickness¶

Specifies the region around boundary conditions that remains unchanged as a factor of level set grid cell size.

smooth_iter¶

Defines the frequency the geometry is smoothed during the optimization process as a number of iterations.

enable_fixed_interfaces¶

Allows specifying if the interface between the design domain (optimized) and non-design domain should be fully preserved. A true input preserves the interface and false allows material to be removed at the interface.

num_load_cases¶

An input required for an optimization scenario with multiple load_case_id. This enables individual load cases to be considered separately during optimization instead of single net load.

starting_design_file¶

Optional geometry file input to start optimizing from, used to continue from final output of a previous optimization step for example.

Example Files¶

Below are examples which go over the LevelOpt workflow setup, post-processing, and results.

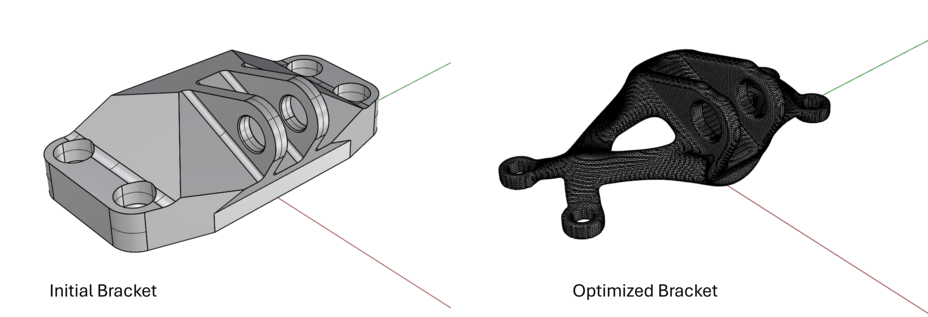

Example: GE Bracket Optimization¶

To download the demo files for this workflow download the zip file here.

$ topopt -s "levelopt_bracket.json"

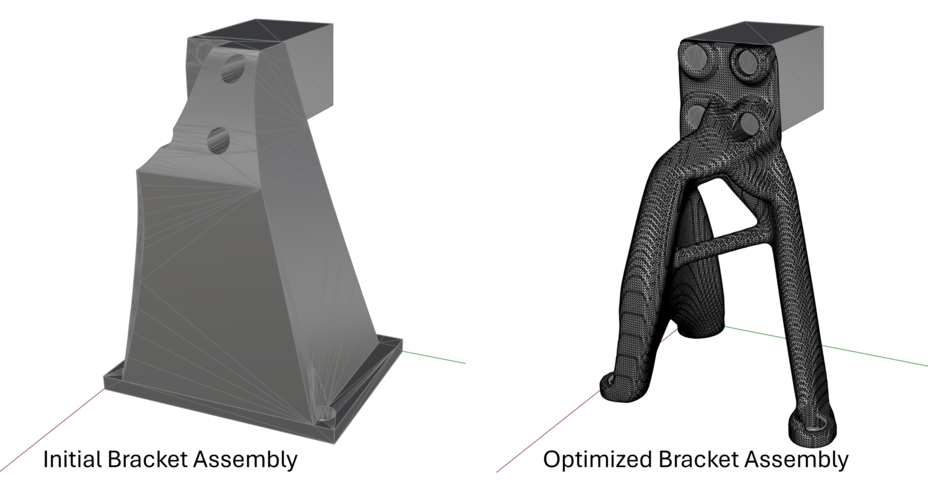

Example: NASA EXCITE Bracket Assembly Optimization¶

To download the demo files for this workflow download the zip file here.

$ topopt -s "levelopt_NASABracket.json"

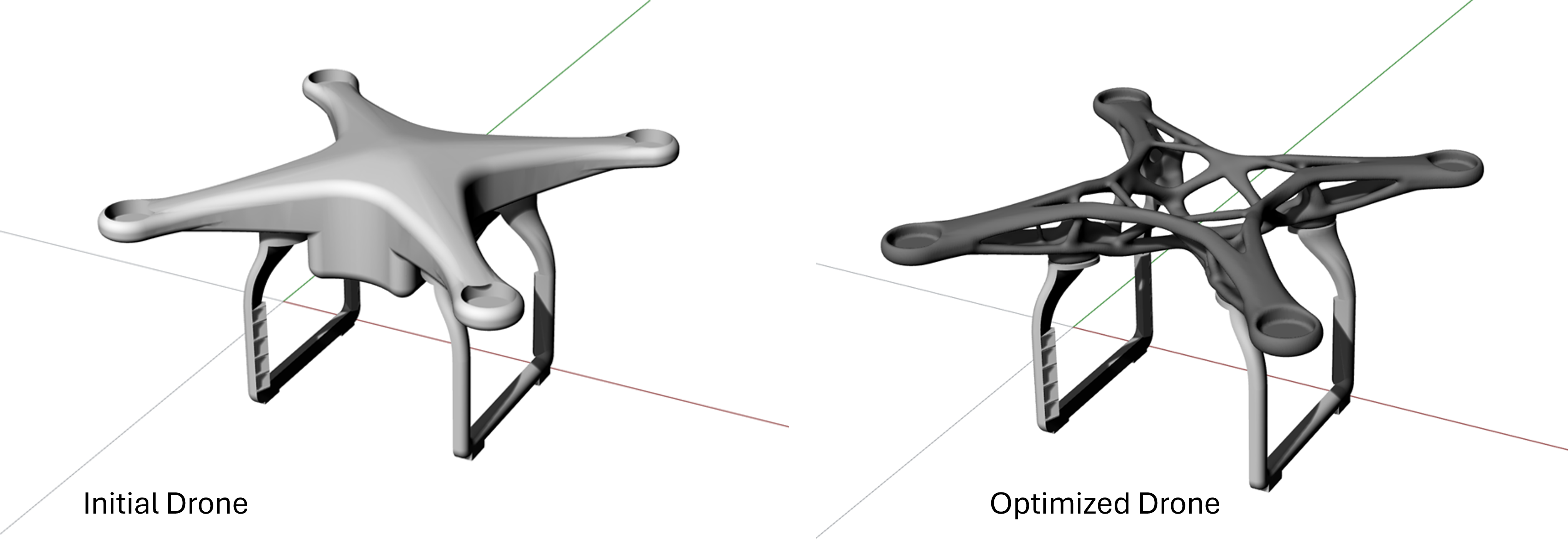

Example: Multiple Load Case Drone Optimization¶

To download the demo files for this workflow download the zip file here.

$ topopt -s "multiload_levelopt_drone.json"

Static Thermal¶

Static thermal requires the scenario json object to have "type": "StaticThermal".

Materials¶

All materials need a density value, and can optionally include a "units": member.

Note that all materials will be specified in MKS unless units are specified.

ThermalMaterial¶

Thermal materials must specify conductivity and specific heat.

A coefficient of thermal expansion can be optionally specified using the expansion_coefficient field.

This example is for steel.

{

"density": 1200.0,

"specific_heat": 1100.0,

"thermal_conductivity": 0.17,

"type": "Thermal"

}

Boundary Conditions¶

Fixed¶

Fixed boundary conditions specify that the boundary is held at a constant temperature and can have a non-zero value.

{

"boundary": "restraint.stl",

"type": "fixed",

"value": 293.15

}

Constant Flux¶

Specifies a heat flow per unit of surface area.

{

"boundary": "face.ply",

"magnitude": 28.0,

"type": "constant_flux"

}

Convection¶

Specifies that transfer of heat from a surrounding medium

{

"boundary": "thermal_plate.ply",

"coefficient": 525.0,

"environment_temperature": 343.15,

"type": "convection"

}

Thermal Metadata¶

Thermal scenarios have an additional metadata value they must specify.

environment_temperature¶

The temperature of the surrounding environment.

OpenMP¶

The intact command line uses OpenMP parallelization.

OpenMP can be controlled by several environment variables.

In general, users will want to specify the number of threads using the OMP_NUM_THREADS environment variable to be

equal to or less than the number of compute cores available.

Logs¶

Load Balance Check¶

The Applied Load Matrix summarizes all externally applied loads and the Reaction Force Matrix summarizes reaction forces from supports in a compact and structured format. This matrix helps validate whether the simulation setup obeys global equilibrium — a critical check for simulation correctness.

Matrix Structure¶

T1 |

T2 |

T3 |

R1 |

R2 |

R3 |

|

|---|---|---|---|---|---|---|

FX |

Fx |

— |

— |

— |

Fx × r₂ |

Fx × r₃ |

FY |

— |

Fy |

— |

Fy × r₁ |

— |

Fy × r₃ |

FZ |

— |

— |

Fz |

Fz × r₁ |

Fz × r₂ |

— |

TOTAL |

∑ |

∑ |

∑ |

∑ |

∑ |

∑ |

T1, T2, T3 → Translational degrees of freedom (forces in X, Y, Z)

R1, R2, R3 → Rotational degrees of freedom (moments about X, Y, Z)

Why Are There Rotational Terms (R1–R3)?¶

Although only forces are applied in the simulation (all torques are converted to an equivalent force distribution), these forces may be applied at an offset from the reference point (usually the origin). This creates moments via r × F — a cross product of the position vector and the force.

Thus, the R1–R3 columns capture the rotational effects induced by the forces, not explicit moment loads.

Purpose¶

This matrix allows:

Consistent tracking of applied and reactive loads

Validation that:

Total Applied Load + Total Reaction Force ≈ 0Detection of setup errors like:

Missing constraints

Incorrectly applied loads

Numerical instabilities

Analytics¶

Intact Solutions gathers anonymous error reports using Sentry.io and anonymous logs using Betterstack.com. You will be notified when installing Intact.Simulation about this data collection.

What is collected?¶

The collected data include

resolution of simulated model

duration of various steps in the simulation process, such as system assembly, solver setup, solving the linear system

crash dumps

Intact.Simulation does not collect details about your specific model or simulation, nor any personally identifying information.

Why is this data collected?¶

This data is collected to understand the size of problems that Intact.Simulation is being used on, to understand its performance and bottlenecks to guide future improvements, and to capture information about failures and defects to improve the software’s quality.

Opting out¶

If you want to opt out, set the environment variable INTACT_NO_ANALYTICS.

For example, using the bash shell, you can do the following to set the environment variable and run Intact.Simulation

INTACT_NO_ANALYTICS=1 ./intact --help

In Windows Powershell, the equivalent command is

$env:INTACT_NO_ANALYTICS=1; .\intact.exe --help